SuperSteel to the Rescue

Associate Professor, Department of Mechanical Engineering

USA TechConnect Global Innovation Awardee

China Rising Star in Technology

Professor Huang and his team are the inventors of SuperSteel, an innovative material that got its name for being both “super strong” and “super flexible”. This breakthrough, which was reported in the prestigious US-based journal Science, could greatly improve the safety of the roads, cars, and planes we use every day for transport.

SuperSteel’s potential applications include auto manufacturing, aerospace, and mass infrastructure such as bridges. It can be produced at a reasonable cost using existing techniques, making it adaptable for industry.

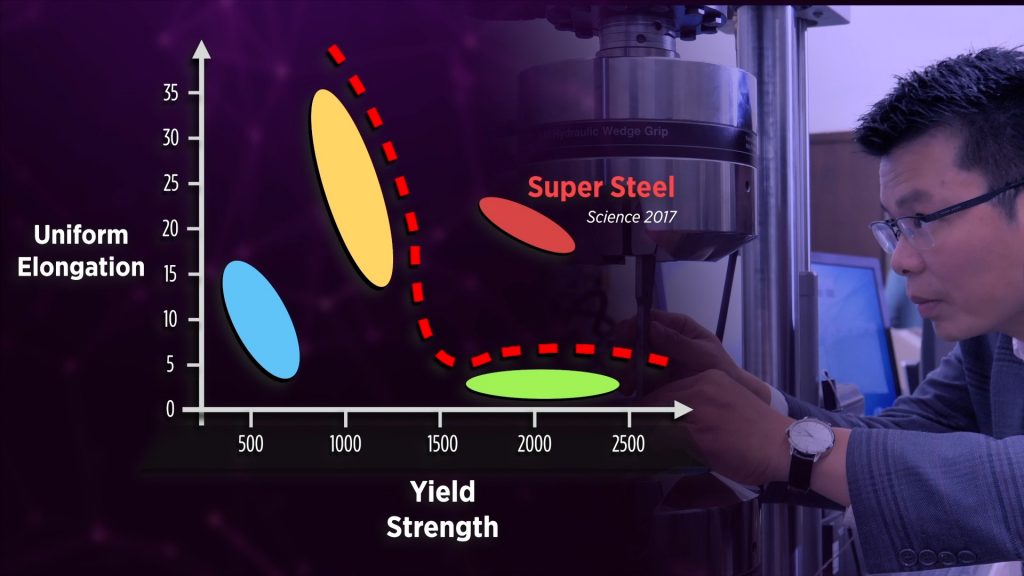

To create SuperSteel, Professor Huang had to overcome a major challenge in the field of material science: the “strength-ductility trade-off”. Conventionally, when strength is increased, ductility – or flexibility – can be compromised. For example, the metals used for making cars may have flexibility, but not great strength. Whereas the metals used for bridges may be strong, but not very flexible.

SuperSteel, which combines the best of both attributes, was developed using a novel deformed and partitioned (D&P) process.

Professor Huang has used another method, called the quenched and partitioned (Q&P) process, to create a different kind of strong and ductile steel for the auto industry. This lightweight metal can be used to design more fuel-efficient vehicles, thereby reducing emissions and protecting the environment.

What next?

Before joining HKU, Professor Huang worked with steel and mining giant ArcelorMittal, so he understands the importance of turning laboratory research into actual products that can improve consumers’ lives.

Several companies are now in discussion with HKU about licensing SuperSteel technology.

Meanwhile, China Baowu Steel, the largest steel company in China, is using the Q&P process to produce steel used by car manufacturers such as General Motors and Nissan.

Professor Huang is also working on developing novel ductile magnesium alloys and antibacterial stainless steel.